Mercedes

Gearbox Controller

5

speed + Lockup

Model

722.6

Contact : of@ofgear.dk

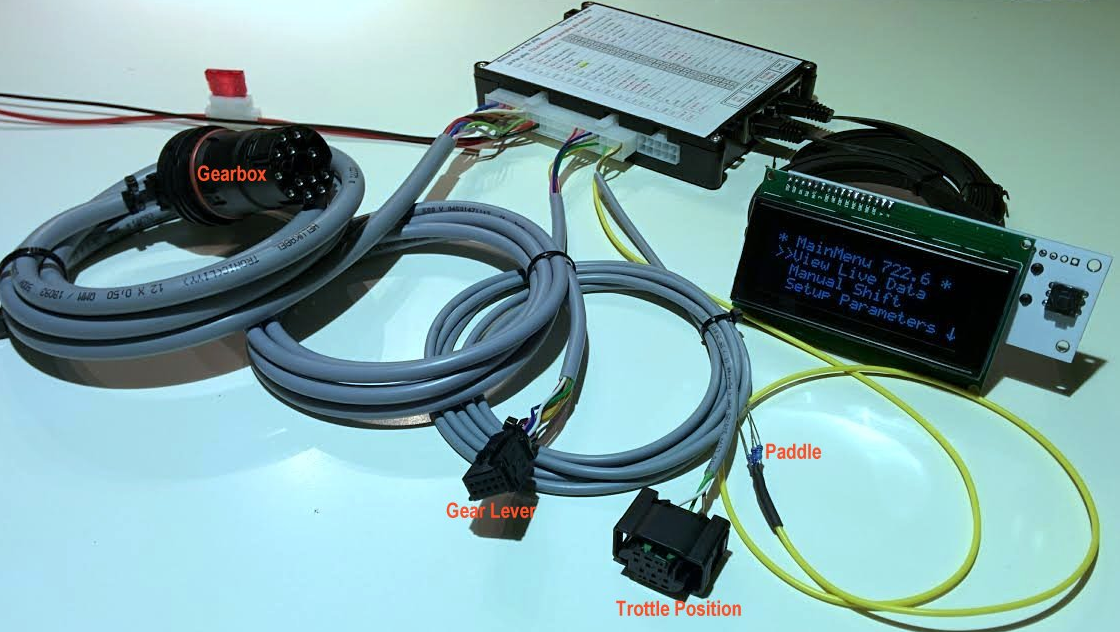

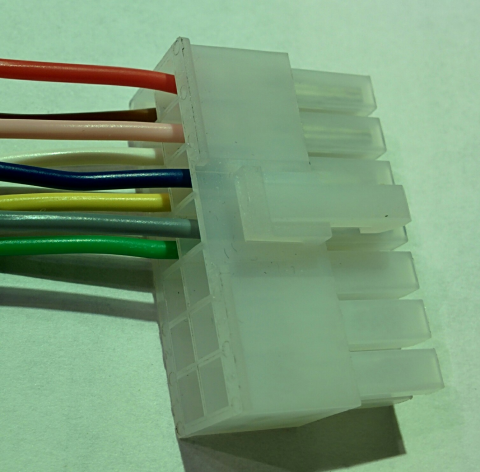

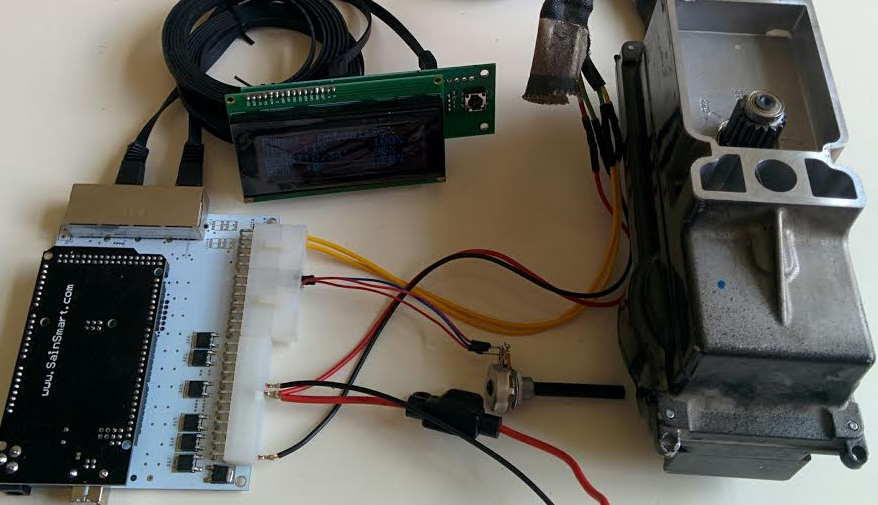

This

is the standard kit,

Including cabling and

plug for gearbox, gear lever, TPS

And a wire with

resistors for connecting to paddle shifters

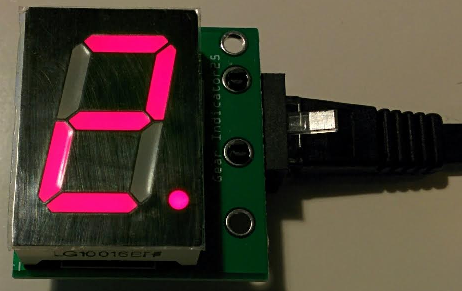

New kit width OLED display (Works as gear

indicator and normal display)

Old kit 4 line text display

Optionel

Gearindicator

1”

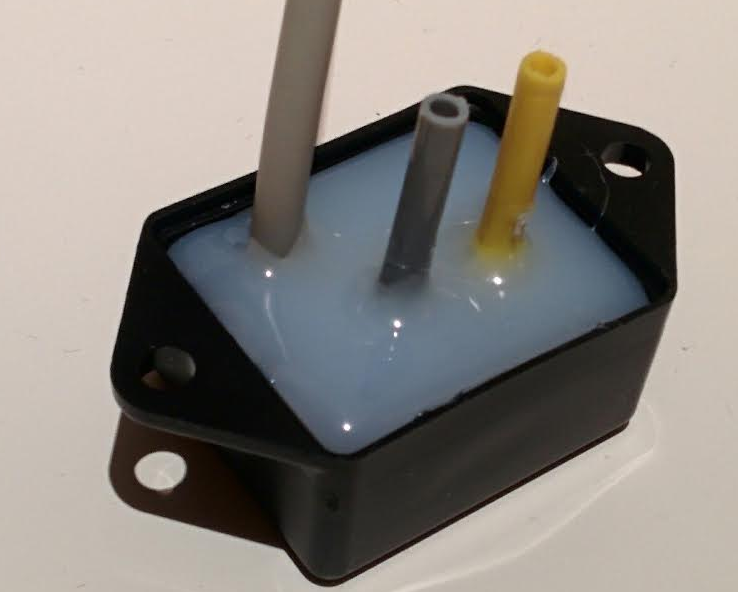

EGP / Boost 3 bar

Boost 3 bar

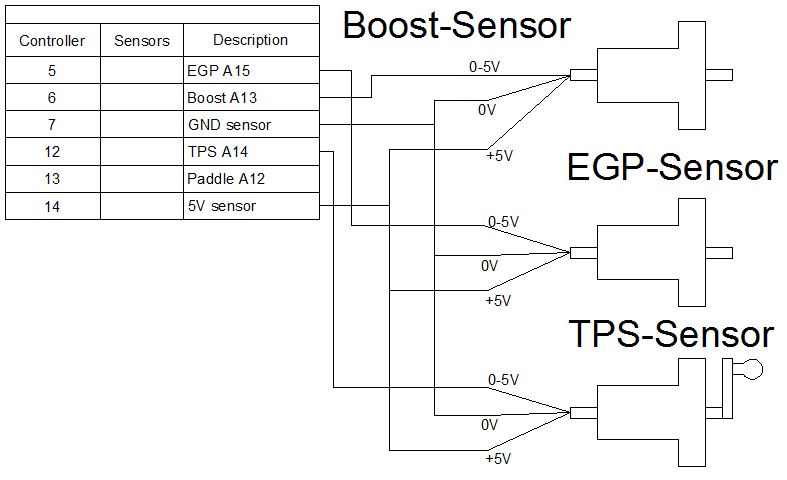

The pressure sensors are

professional type bought from www.Mouser.com, and has a gel over the die to

protect from harsh environments, and can measure 3 bar boost/EGP over

environmental pressure.

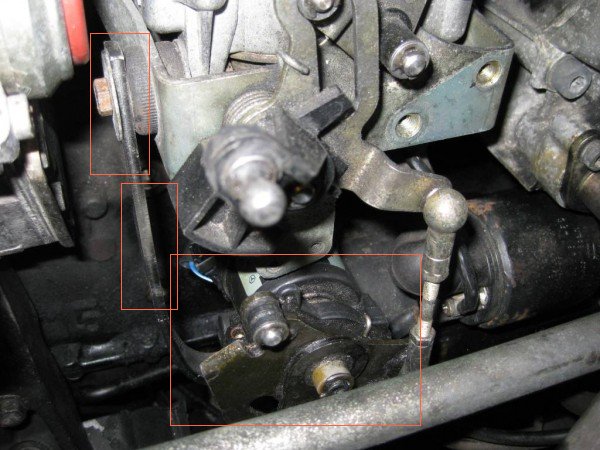

Here

it is connected to gear lever and

TPS (throtle position

sensor)

Boost solenoid / EGP sensor / boost

sensor. Only needed if used as boost

controller

Getting started / installing

the controller

First,

connect all plugs.

Gearbox:

Connect the large, round, multi-pin plug directly to the gearbox

Gear lever:

Connect the rectangular gear level plug to the gear lever.

TPS:

Connect the TPS sensor plug to the TPS sensor.

Boost

sensor: Connect the boost sensor to the intake manifold,

(Boost sensor is better for Turbo cars,

especially if it is late spooling turbos)

Then Connect Power

Black to ground makes sure you have a good

connection.

Red to a 12V supply that becomes live when the

ignition is switched on. Use an 8 Amp fuse on this wire.

Now before starting the engine, you have to

calibrate the TPS (Throttle Position Sensor).

This

process teaches the controller about the signal it can expect to receive from

the TPS when the throttle pedal is both fully depressed and when it is not

depressed at all.

Put the “W/S” switch into the W position

(if you have the Mercedes Gear Lever)[A1] ,

1. Turn on the ignition so that

the controller is powered up, but do NOT start the engine.

2. Press the joystick down until

“SETUP” is shown on the display

3. Press the joystick right, to

enter this menu

4. Now that you are in the SETUP menu, Press the joystick down

until "Setup TPS " is

displayed.

5. Press Joystick right, to

enter this menu.

6. Now with 0% TPS (throttle

pedal not depressed) press the joystick UP

7. Then press the throttle pedal

fully (100% TPS) and press the joystick DOWN

8. Put

the “W/S” switch into the S position, and repeat steps 1-8. (Only

if you have a W/S switch, otherwise you are done)

Gear Lever

Put the “W/S” switch into the W position (if you have the Mercedes

Gear Lever).

1. Turn on the ignition so that

the controller is powered up, but do NOT start the engine.

2. Press the joystick down until

“SETUP” is shown on the display.

3. Press the joystick right, to

enter this menu

4. Now you are in the SETUP menu, press the joystick down

until "Lever Setup" is

displayed.

6. Press Joystick Right, to

enter this menu

7. If you have the 10 pin plug

in the Gear Lever PRND4321. Press Joystick UP or Down to get “0”

If you have no plug for

Gear Lever set to “1” (and ignore step 9, unles you have mounted a switch for

switch W/S)

8. Press Joystick Right to save

9. Put

the “W/S” switch into the S position, and repeat steps 1-8. (Only

if you have a W/S switch, otherwise you are done)

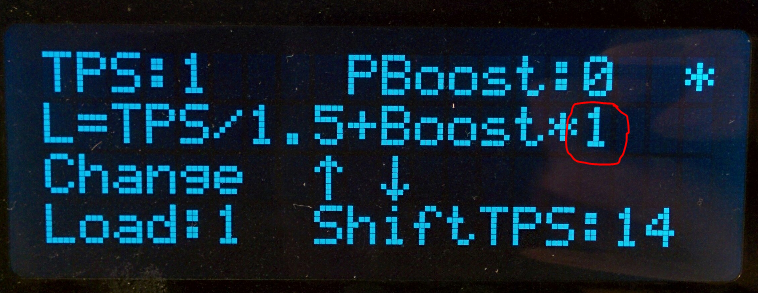

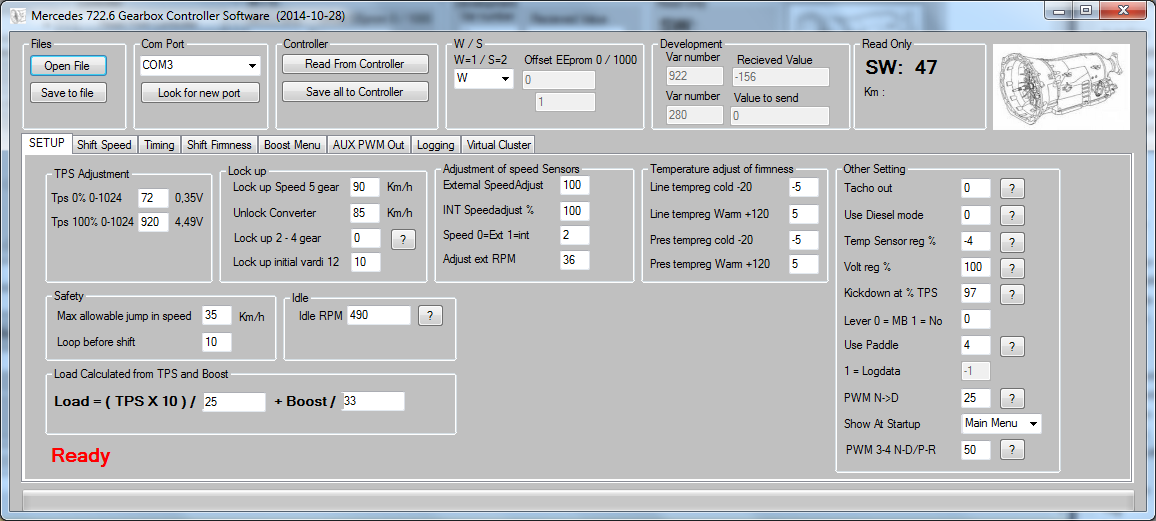

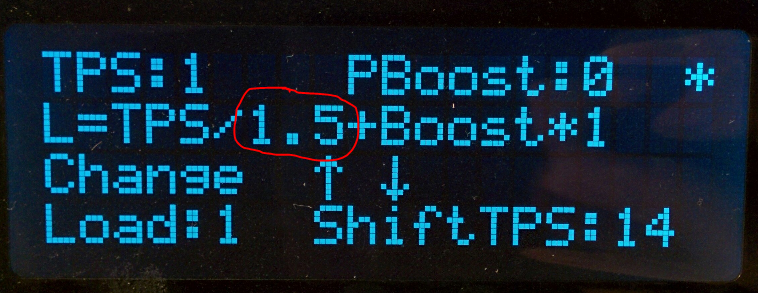

Load

For turbocharged diesel engines

with a boost sensor, the torque of the engine is calculated as a combination of

TPS and boost.

This means if a diesel engine

with a peak torque of 750Nm has 250 Nm with no boost, and 100% TPS, the engine

is at around 33% torque. When the turbo kicks in and boost pressure is at 2

bars, we then get the remaining 66% torque and peak output of 750 Nm.

For a Gasoline car it is

different here we only use TPS, 100% TPS is 100% torque.

“Setup Parameter” -> “Load - TPS Boost”

Diesel cars

where boost sensor is mounted set it to 2.5

Gasoline

cars 3L (6 cyl) set it to 1.5

Gasoline

cars 5L (V8) or more set it to 1

When the

number is changed it is saved automatically, no need to press right to save

this setting.

“Setup Parameter” -> “Boost Part Load”

Diesel cars

where boost sensor is mounted set it to 33

Gasoline

cars 6 cyl set it to 1

Gasoline

cars V8 or more set it to 1

Here you do

have to press right to save after the number is changed to the desired value

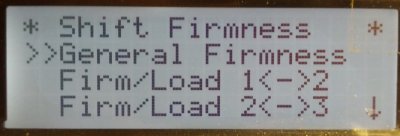

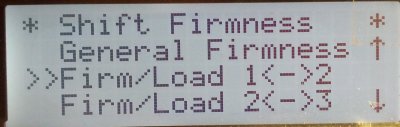

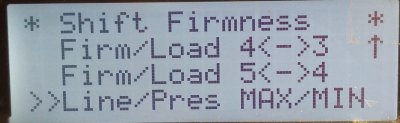

Shift Firmness.

When you first drive the car, be take careful notice of how hard the

shifts are.

If all shifts are too soft or too hard it can be adjusted with the

following setting.

“Shift Firmness” -> "General Firmness"

If shifts are too soft, reduce the number to get harder shifts.

If shifts are too hard, increase the number to get softer shifts.

Please be aware that if shifts

are too soft, it can cause a problem where a shift does not complete and it

stays in the gear it was in.

A shift that is a little too

hard is always better than a shift that is too soft.

External Speed

The best

situation is to have the controller connected to an EXTERNAL SPEED SENSOR.

But as many

of the old cars do not have one, the controller can work with the speed sensors

internal to the gearbox.

"Use int speed/Rpm" (to decide if you are going to use an External speed sensor or not)

In software

versions > 157 there are two separate menus. One for “Speed EXT/INT” and another for “RPM EXT/INT”

PUT the “W/S” switch in the W position

1. Turn on the ignition, but do

NOT start engine.

2. Press the joystick down until

“SETUP” is shown on the display.

3. Press the joystick right, to

enter this menu

4. Now that you are in the SETUP menu, Press the joystick down

until "Use int speed/Rpm" is

displayed.

5. Press the joystick right, to

enter this menu

6. Press the joystick up or down

to select “0, 1 or 2” as per the

list below.

0 External Speed and RPM sensors are connected

1 External RPM sensor is connected and internal speed sensor

is to be used

2 No external sensors are connected and both Km/h and Engine

RPM is read from internal gearbox sensors.

7. Press the joystick right to

save

8. PUT

the W/S switch in the S position,

and repeat points 1-7.

An external

speed sensor is absolutely preferable, as there is a limitation on the internal

speed calculation, since the speed cannot be read while shifting.

After connecting the External speed sensor, run the car slowly (10 km/h)

and see what the speed says, in “LiveData” if it is not correct it should be

adjusted in the setup menu "Adjust

Ext Speed % "

If you want to get the most out of this

controller

You should

get an overhauled gearbox, if not you run the risk of getting the engine RPM

jumping up during shifts, I have seen this myself, and heard it from others but i have only seen it happen

between 3rd and 4th gears. I have not seen this problem on any other shifts.

If you want

to shift gear under 100% load I am just preparing you that you can see a jump

in RPM between 3rd and 4th gears.

I have it even

in my E55AMG box and live with it fine.

I just do

not want to be responsible for your gearbox not shifting 100% correctly ;-)

And as much as I hate to say it, here it is…

This

product comes with no warranties or guarantees of any kind. Both installation

and use of

this system

in any vehicle is done at the risk of the owner / operator of the vehicle. The

developer /

seller of this system cannot be held responsible for any loss, damages or

injury

caused

either directly or indirectly by the installation or use of this system. The

system is

intended

for off road use only. Be advised that the system will produce changes in the

drivability

of your vehicle.

Q & A

Q: Can I find any 722.6 on the yard and it will

work?

A: As far as I have seen, any 722.6 is OK. The

usual problem is that it jumps a little up in RPM between 3-4

Q: What gearbox is the best for high power

project. 600 Nm or more?

A: W5A580 AMG box is one of the strongest.

Q: What Year is the best?

A: As new as possible they have only got

better and better.

Q: if I find a W5A580 AMG box, is it then just

mount and go?

A: Get it as new and low mileage as possible

Q: What is the best to do if i want the best of

the best?

A: Have the gearbox overhauled and have

everything gone through; seals in

valve body and clutches and have their clearance tightened up beyond Mercedes

specs. The best thing to do is to set them up to have about as tight a

clearance as possible but not too tight so that they burn from drag.

Q: But can I use an old worn out box if i just

want 5th gear and lockup not for racing?

A: Everybody’s requirements are different, but

if you let’s say run it in manual mode and let off the throttle at every shift,

then yes, it is possible, also in automatic mode if it is cruising not racing.

Q: My box was working perfectly in the donor car

and now it is slipping between 3rd and 4th gear.

A: You

have to remember that the transmission had torque management, meaning the donar

car was limiting power during shift. Because of this, you will never see the

state the gearbox really is in, as the clutches get worn out Mercedes adjusts

for that by letting the shift take longer, meaning removing momentum from the

engine for a longer time.

Q: Can a

Normal 722.6 from a standaard E300 turbodiesel hold a momentum of 600 Nm?

A: Yes it

can hold that but shifting under max power is a different case, from my

experience the 1->2 is fine and also the 2->3 and 4->5 but we are on

the limit here.

Q: The

W5A580 does not fit the OM606 what do I do?

A: Get the

Converter and bellhousing from 722.6 which was originally mounted on OM606

(Diesel Engine 24V)

Q: I have an

OM606 and I dont want to mess with the bellhousing what should I look for?

A: Find a

gearbox from a E320 CDI as new as possible, they are built to high momentum. (This information could

be wrong as I have heard it does not fit, I will try to find out) (The 320CDI

box DOES NOT FIT OM606 unless the bell housing is switched.)

What I am trying to say is that you should get the gearbox adjusted and

looked after before installing if you want a system that is working perfectly.

If you can live width a little slipping when shifting under load, then

try to install what you have but that is totally up to you.

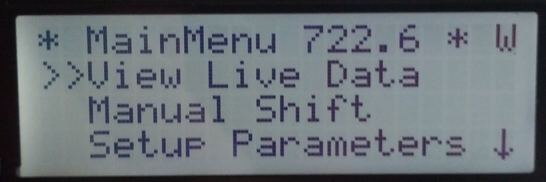

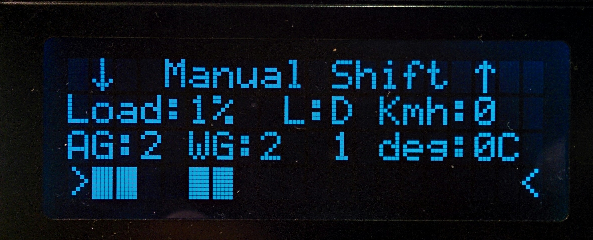

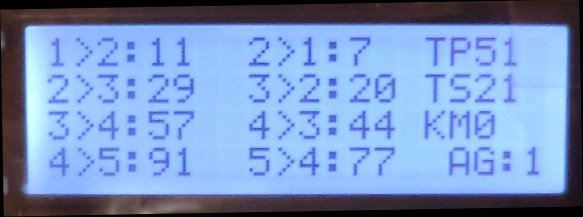

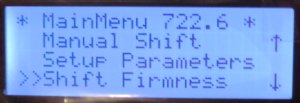

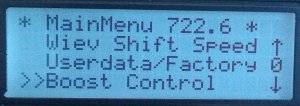

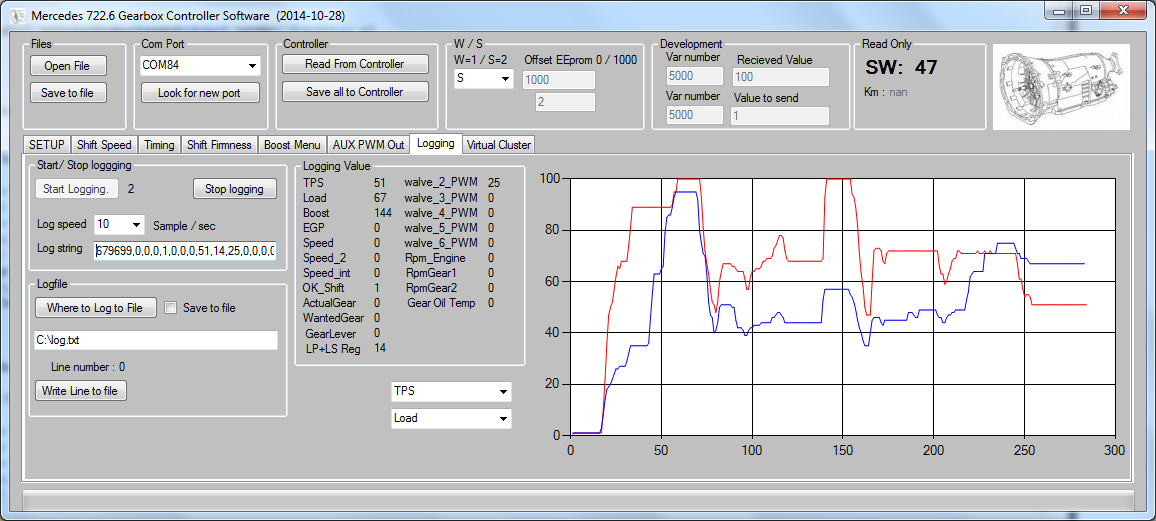

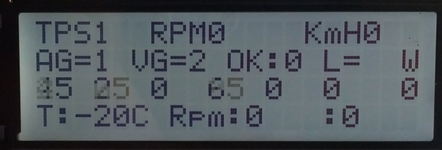

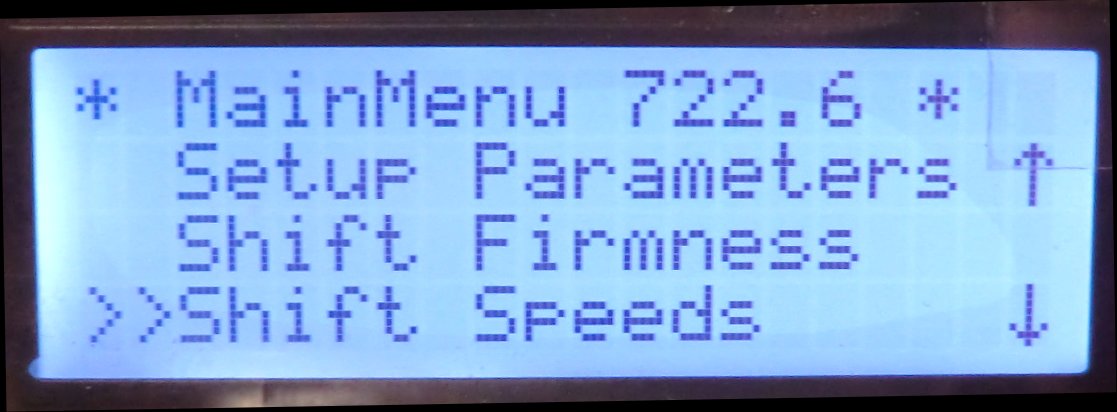

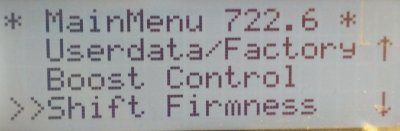

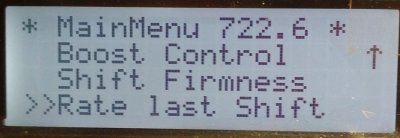

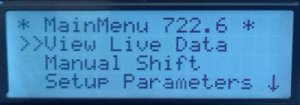

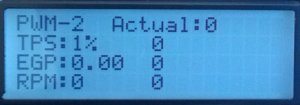

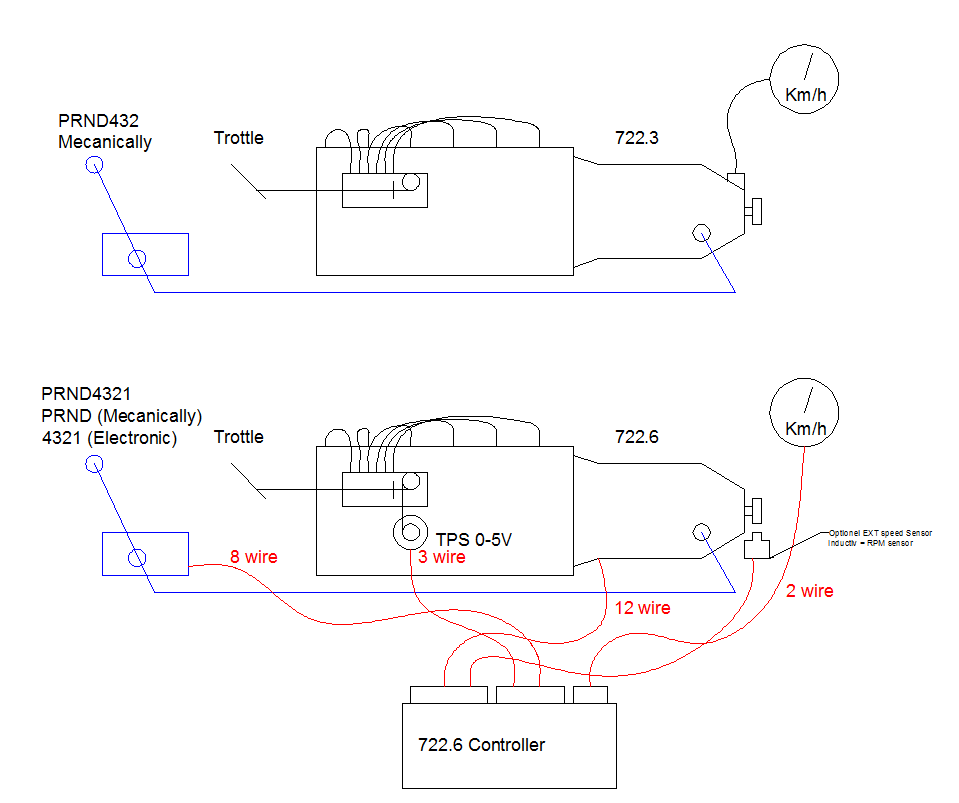

main menu

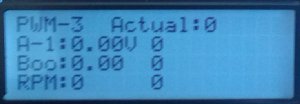

Live Data

Here you get TPS position “Throttle Position Sensor 0 - 100%”

Engine RPM, if taken from inside the gearbox, value is only valid when

driving

Km/h taken from inside gearbox or external sensor.

AG : Actual gear used

VG : Wanted gear

OK : if 0 the box controller is waiting, if 1 then it is ok to shift

gear, only 1 gear shift / 2 sec

L : Gear Lever position P, R, N, D, 4, 3, 2, 1

W : W / S Winter / Sport

Then all the valves, used for problem solving under development, but

nice to watch.

T : Temperature inside the box, only valid when in gear

RPM internal part 1 / internal part 2

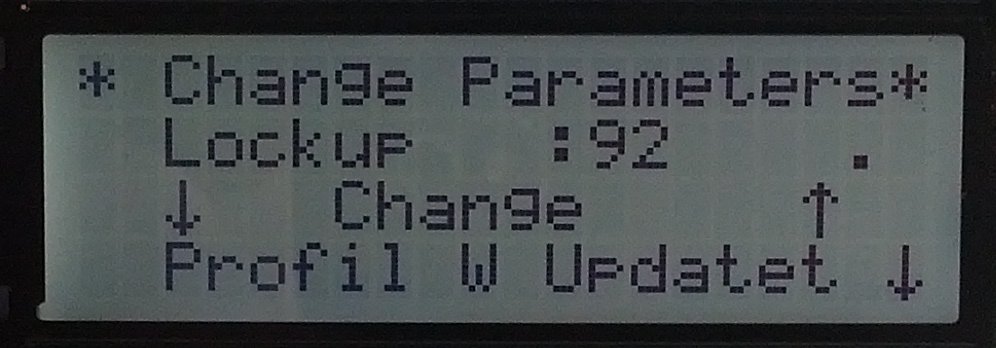

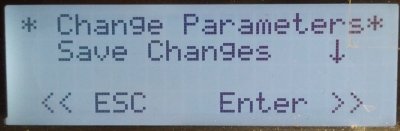

SETUP

When you change a value you have to press the joystick right to use it,

If you want it to be saved permanently, you have to save it to default under

the menu called “Userdata/Factory” / “Default W”, otherwise your changes will

be lost when the controller is turned off.

Change value by moving the joystick UP / Down.

Press the joystick right to save it.

Parameters to change in

“SETUP”

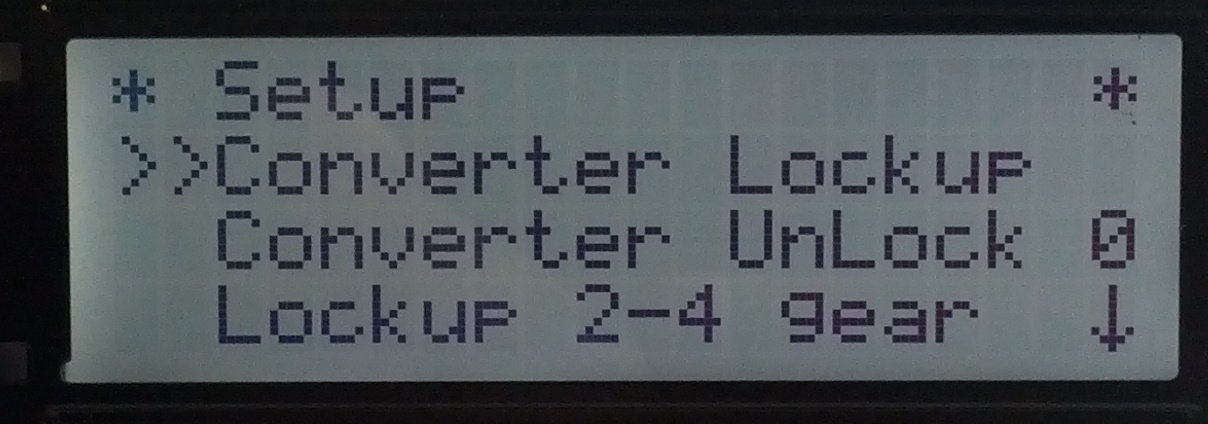

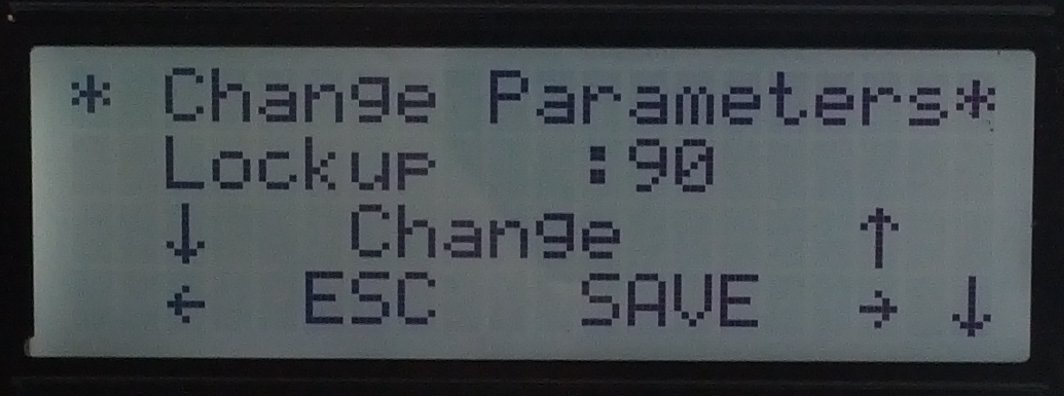

"Converter Lockup "

The

speed in km/h at which to lock up the torque converter in 5th gear.

"Converter Unlock "

The

speed in km/h at which to unlock the torque converter in 5th gear.It must be

lower than the lockup setting above.

0 = No, (only lockup in 5th gear)

-1 = Like 1 but do not unlock if TPS goes below 10% (only lockup i 5

gear)

1 = Lockup also in 2 - 4 gear, if you put gear lever in position 4 you will

have lockup also in 4 gear, this is useful when pulling heavy uphill.

2= always lockup in 2-5 gear also if the lever is in “D”

From Software 92 and UP

3= Like 2 but also no unlock with no throttle.

4= Like 3 but also shifts gear with locked converter, converter only

unlocks if below 30 km/h This is only useful at Racetrack :-)

5 = Special only unlock if speed is below 10 Km/h and lock if in “2” and

speed > 10, this is a special setting for an Electrical vehicle (only from ver_140)

6= Lockup over a switch 12V in on (D0 kickdown 12V in), but then you can

NOT use kickdown on this input, no soft lockup in this mode as it is for Racing

/ Drifting (only

from ver_143)

7= Lockup if speed bigger then 30 km/hr and locked under shift And it

unlocks if TPS > 75% And it unlocks if speed is < 30 km/h Does

"NOT" unlock it TPS < 10%

(only from ver_170)

8= Lockup if speed bigger then 30 km/hr and locked under shift And it

unlocks if TPS > 75% And it unlocks if speed is < 30 km/h Does unlock it

TPS < 10% (only

from ver_170)

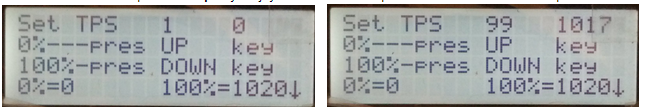

"Setup TPS "

To set up TPS to get exactly 0% when pedal is released and 100% when

fully depressed, even if you only supply maybe 4 volts at full throttle. This

is very simple you press the throttle to 100% and press the down key, let go of

the throttle and press the UP key, thats it, TPS is calibrated, look at first page for more on this issue

"LOAD - TPS Boost "

if set to “2”

then it means that the Throttle depressed 100% gives 50% Load, Boost gives the

rest.

"Boost part

load "

If set to lets say 33

{

EXPLAIN

Load = TPS / 2 + Boost * 33

EKS “50 / 2 + 1 * 33 = 25 + 33 = 68% load

}

"Idle RPM "

Only used in some cases, if components is mounted. and only if there is

external RPM-signal as the calculated RPM signal will always be 0 at stationary

car. it has to be set higher then 500 RPM, to get an output.

From ver 123

If set to exatly “510”

something special will happen it will adjust idle to 800 when Gearoil temp is

below 45 deg, and to 650 when hotter.

"Max Boost mbar. " Moved to

Boost menu

Only used in some cases, if

components is mounted.

“Volt reg +/- "

Here

you can adjust the Voltmeter if not showing correct value.

“Temp reg +/- "

Here

you can adjust the temperature +/- 20 deg

this is only to be used if you know it is displayed wrongly.

"Kickdown at %TPS "

if set to 97 then you will have kick-down if TPS > 97 if set to 101

you never get kick-down.

If you set it to 105 Kickdown would be triggered from external 12V

source.

"max speed fail "

There is a safety function not allowing km/h to fall down to fast,

should be set to max 20

"Slow upshift "

The higher the number the

slower upshift, by instant release of throttle, it suppresses unwanted

upshifts, when cruising slow around in the city.

"PWM N->D P->R " Called

Garage Shift by Mercedes

IF you have hard shift when shift in to D and R the the number must be

higher, too high it will not engage.

Default is 25, but you can make the P/N -> R and P/N -> D softer by higher number try 35, but if it

does not engages you have to lower the value, the first 2 times you engage R or

D this value is not used, to make shure we have engagement first time.

(only in SW 135 or

higher) If it will not engage in D or R set to 15

"PWM 3->4 N-D/P->R (only if SW >

ver_136)

The Valve for the 3-4 shift is triggered width a PWM signal when

shifting from N->D or P->R this is default 50.

This is to give a smoother engage.

But if you have any problem that it sometimes not engage, set it to “0”

"Adjust ext RPM"

Default is 36, if RPM show too high lower this

number, only use if you use external engine RPM

In Software > 157 there is two seperet menu

One for

“Speed

EXT/INT”

Use internal speed from gearbox, or external

speed.

“RPM

EXT/INT”

Use internal RPM from gearbox, or external RPM.

The

internal RPM will always show 0 if car is stationary, and engine is running as

the converter is slipping, this is normal.

"Use int speed/Rpm"

Use calculated Km/h from the

internal parts in the gearbox if set to

0 Then Contrroller need both RPM and Speed from external

source.

1 then you only need external RPM, Speed is calculated from

inside the Gearbox

2 then both Km/h and Engine RPM is calculated from inside the GearBox

5 (for speed compare, internal / external to werify rigth

gear)

6 (for speed compare, internal / external to werify rigth gear)

+ External RPM

After change save settings and

power off and on again, then changes is made

"Temp Line -20deg "

Adjust the line pressure at

cold

"Temp Line 120deg "

Adjust the line pressure at

Hot

"Temp Pres -20deg "

Adjust the shift pressure at

cold

"Temp Pres 120deg "

Adjust the shift pressure at

hot

"delay 3-4 "

Only use if you have problem with slip in 3-4, if you have, start with 5

and 1 up at the time, until it goes away, do not go over 15 then you have a bad

box.

(only in SW 120 or higher)

If you set it to

exact “-1” the 3 -> 4 shift only happens if TPS is below 45% that is great

as you let of the TPS when you want the shift, and it shift smooth.

(only in SW > 150

or higher)

If you set it to

“-1 to -9” the 3 -> 4 shift only happens if TPS is below -1 = 10% and -9 =

90% that is great as you let of the TPS when you want the shift, and it shift

smooth.

"Reset Km Counter " (only in SW 128 or higher)

Press

Right This will reset to Total Km

to “0” Km

Press Up

this will add 1000 Km at each

press

Press

Down This

will subtract 100 Km, that mean you can adjust to a precision of 100 km.

"Lockup Soft / Hard"

1 = hard 30 = soft

"Use Paddle shift "

Use paddles on analog 9,

0 = disable

1 = Read the value for testing

2 = Read the value and activates the horn output

3 = Paddle shift activated

4 = Paddle shift activated, and if in main menu, and paddle is pressed

it shift to manual instant, and goes back to auto if you drive very slow in

high gear, (only in

SW 95 or higher)

"EXT Speedadjust "

Used to adjust External speed in % can be used if you change your Rim

Size.

"INT Speedadjust "

Used to adjust internal speed in % can be used if you change your Rim

Size.

"Time bet shift " = time between shifts

Used to change the minimum

time between shift, if set to 1000 mS then you can shift from 1 to 2 then you

have to wait 1 sec to shift 2 to 3,

This time is also used in

automatic mode but here is added 500 mS this means that when the time is set to

1500 mS “Standard ” it is 2000 mS in automatic.

"0 point boost "

Moved to Boost menu

where the boost sensor has 0

bar on the 0 - 1024 scale if it is a 3 bar sensor it would propably hav a range

from -1,5 bar to 3,5 bar 0 - 5 v and the

value here should propably be set to 300.it can be tested on the 2. live data

page, where you press right on the live data, you can press right to get the

second page. you should adjust until you just see a little boost when engine

not running.

"Max boost at 5v " Moved to Boost

menu

This is the max boost your

sensor can handle. A 3 bar boost sensor has 3 bar at 4,5 volt, 3,5 bar at 5

volt, this value has to be set to 350 “mBar at 5 volt”

“Show on Display at Startup”

in live data, you can change

what to display on line 3

0 = Normal, just main menu

1 = Boost menu, Live Data (This is if you just

use the controller as Boost Controller. and want to have live data all the

time)

2 = Start up in Manual mode, (RACEMODE or if you just want Manual all the time.)

3 = Live Data

“VNT Boost/EGP” ( Moved to Boost menu)

Boost controller is used

1, 2, 3, 4 is for VNT Turbos 4

different algorithm to adjust boost

5 is for Normal Turbo

6 is for Normal Turbo more

aggressive limit

7 is for Normal Turbo even

more aggressive limit

8,9,.....................

20 extreme aggressive limit.

“Lever setup”

0 = MB standard lever

1 = No lever, N, P and R &

D can be detected but not 4-3-2-1

2 = Special For a special

gearbox having a 120 OHM output when in “R” (gives reverseligth output on

AUX-3)

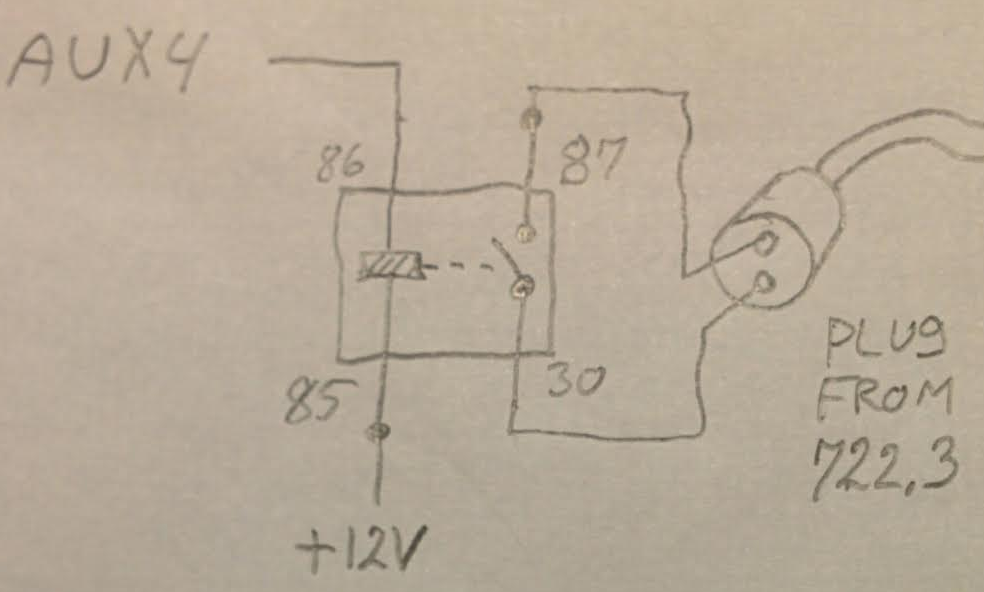

“Limit Engine Power under

shift” (Not in this setup

menu, but i think you would try to find it here)

Under “GeneralBoost” goto Use PWM - AUX-4,

The following happens for different value

2, you

get instant 200 mS 100% PWM

3, you

get instant 300 mS 100% PWM

12 you

get 100 mS delayed 200 mS 100%

PWM (1 is

100mS delay the 2 is 200-100 = 100 mS signal)

25 you

get 200 mS delayed 500 mS 100%

PWM (2 is

200mS delay the 5 is 500-200 = 300 mS signal)

By the

way Engine limit only works at TPS > 20% (prevent stop engine at low RPM)

If you want to Limit Power on

Mercedes Gasolin car, where before a 722.3 was

From Switch S65 on Gearbox width

1K Ohm resistor Pin 1 and Pin 2 width a relay

Manual Shift

Use the joystick up/down to change gear, 100% manual / or paddle

shifters. / or switches connected to a rally type shifter

It is still only possible to change gear one time every 2 sec

(Adjustable in setup menu.)

It is only possible to downshift the same as a kickdown would, Safety

that you not turn over the engine.

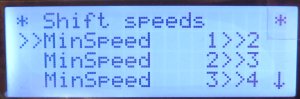

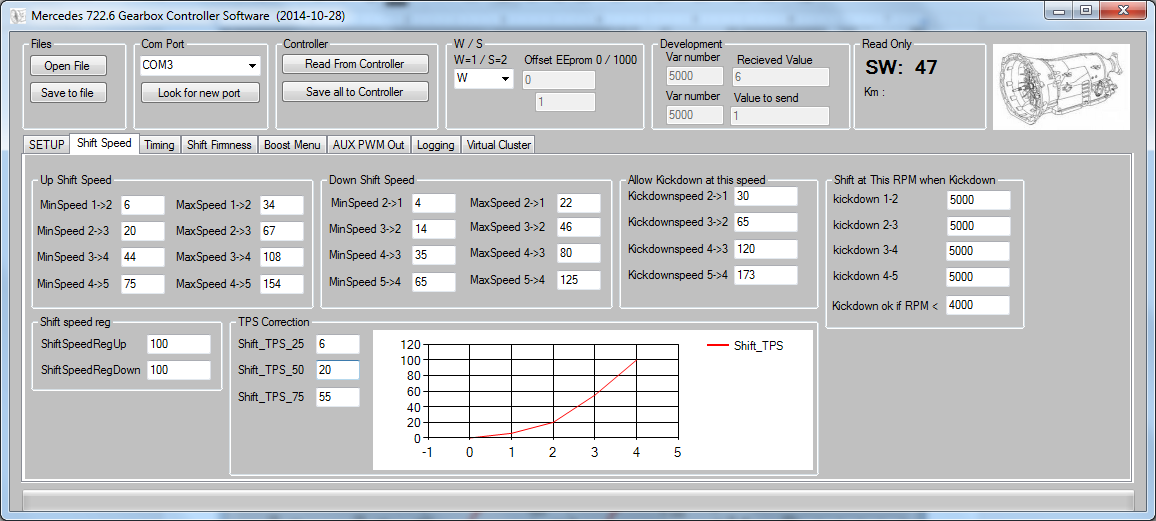

Shift Speeds different gears

Here you can see all UP / DOWN shift at actual TPS,

You can test it by stopping the engine, go to this screen, and press the

throttle, to see when it would change at that TPS.

Shift Speeds

Here you can change the value of all shifts

0% throttle

1-2 called Min 1-2, Upshift

100% throttle 1-2

called max 1-2 Upshift

0% throttle

1-2 called Min 2-1 Downshift

100% throttle 1-2

called max 2-1 Downshift

Kickdown ok 2>>1

If the Speed is lower then this value it is ok to shift down to 1 gear

at kickdown

RPM Kickdown 1-2

At this RPM it will make upshift from 1>>2

Kickdown ok RPM

Downshift width Kickdown will only happen if RPM is below this value

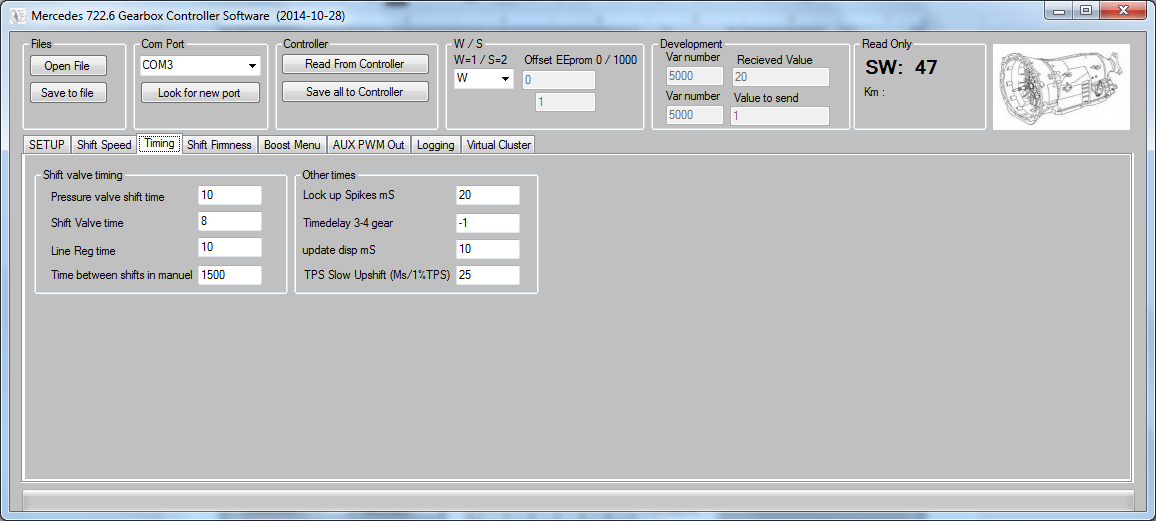

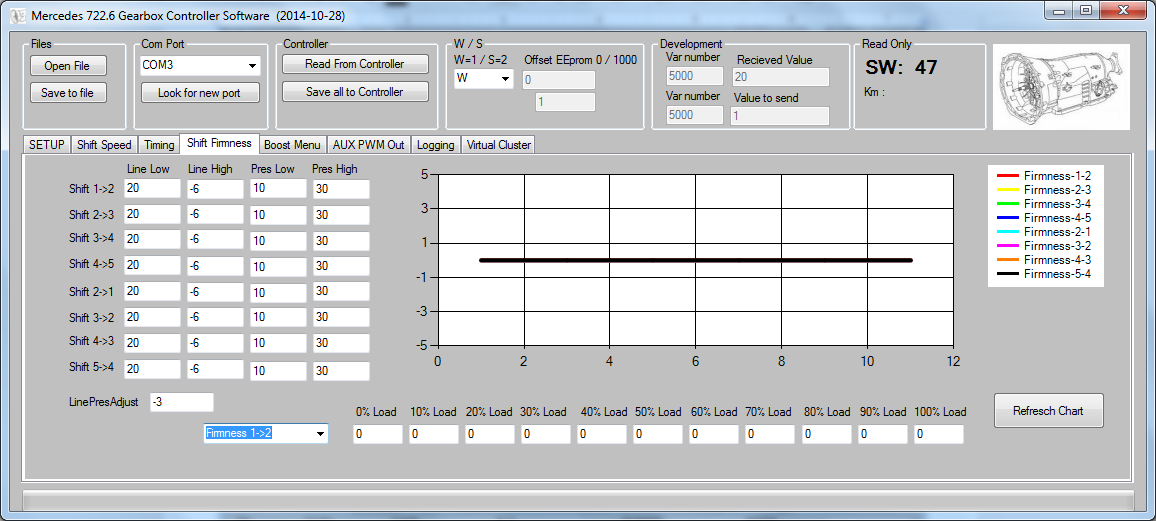

Shift Firmness

LineLowLoad 1>>2 Default value = 20 (Higher

value = Softer shift at low load)

PresLowLoad 1>>2 Default value = 30 (Higher

value = Softer shift at low load)

LineHiLoad 1>>2 Default value = -6 (Higher

value = Softer shift at High load)

PresHiLoad 1>>2 Default value = 12 (Higher

value = Softer shift at High load)

LineLowLoad 2>>1 Default value = 20

PresLowLoad 2>>1 Default value = 30

LineHiLoad 2>>1 Default value = -6

PresHiLoad 2>>1 Default value = 12

If you find the shift from 1>>2 to hard at very

low load.

Then try this

LineLowLoad 1>>2 LineLowLoad = 22

PresLowLoad 1>>2 PresLowLoad = 32

Remember to press the >> key to save the values.

And before shutting the car down remember to save it permanently under

“Userdata/Factory (” version 2 saves it automatacally.)

And do the same for high load,

if you find the shift to hard or too soft.

When this is done and you find

that the shift are too soft or too hard at lets say 50% load, you need to

change those

When you have set up nice soft

shift and good hard shift. then you can fine tune with number below

"Load

at 25% load" if you have to soft

or too hard shift at 25% load if to hard lower the number

"Load

at 50% load" same but at 50%

"Load

at 75% load" same but at 75%

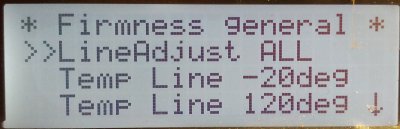

The whole new Shift Firmness

MENU (from

version 117) Need to be testet some more

In this menu you can adjust all shiftfirmness parameters manuelly

In the gereral Firmness

You can adjust correction for temperature, and adjust general

Linepressure

From ver 139

“LineAdjust” All changed to “Firmness All L=H”

L=H means Lower number = harder shift

This now adjust both

LinePressure and ShiftPresssure, Lower

number = harder shift, higher number =

softer shifts.

If you want to adjust the hardness for different load, go in here.

If you want the shift to bee a bit harder at 30% load then just adjust,

higher number is harder shift, but only at 30% load

before you leave this menu it is possible to save changes, it

automatically saves in “W” or “S” depending on the switch position.

The last menu in Shift Firmness is the Min / Max at any gear, Just leave

it, its fine as it is :-)

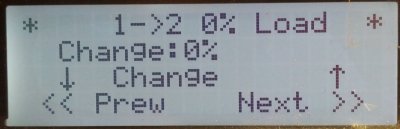

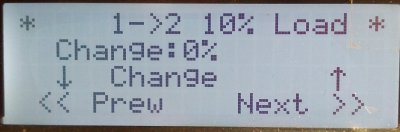

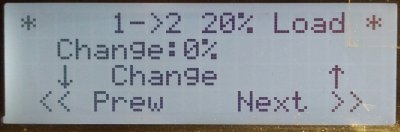

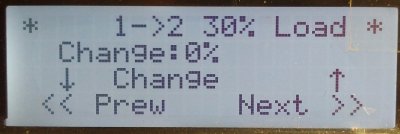

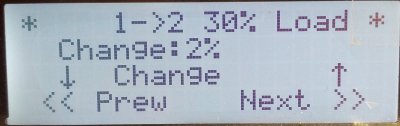

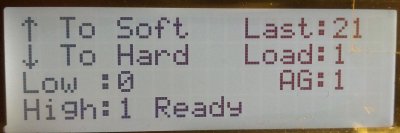

Rate Last Shift MENU (from version 117)

This is the Rate Shift Menu

When the gearbox have shifted you see the last shift, and at what load,

the shift was done.

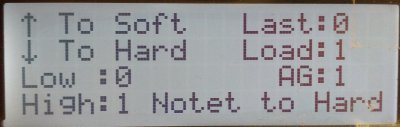

On this oicture below it has shiftet from 2->1 at load 1% = no load

Here i pressed the joystick down, to tell the controller to make it a

little more smooth next time.

And the controller reply width “Notet to hard” and it will make it more

smooth next time.

There is 10 different load points, on every shift. and they are

different on up and down also.

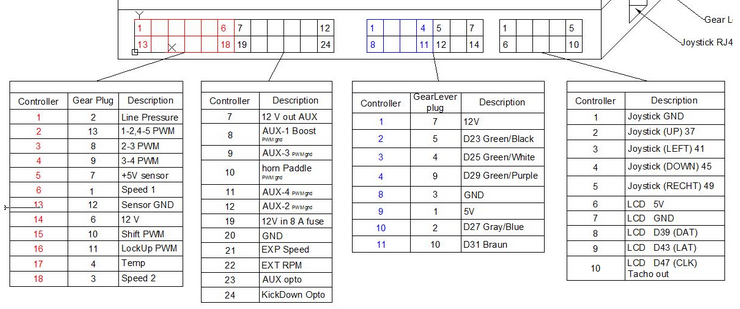

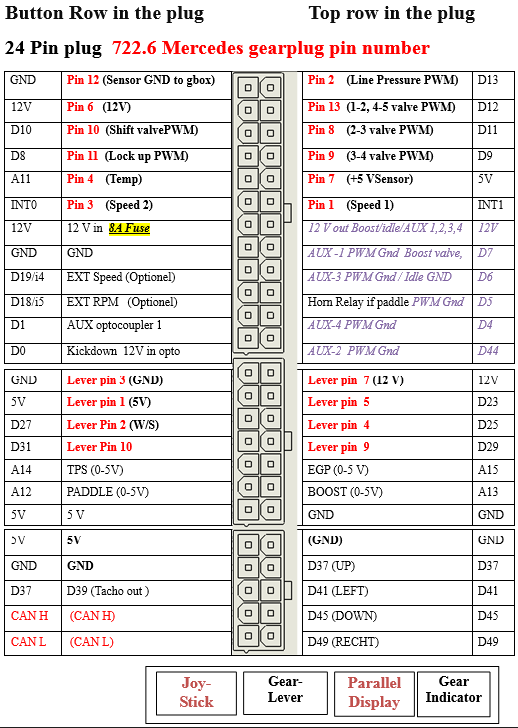

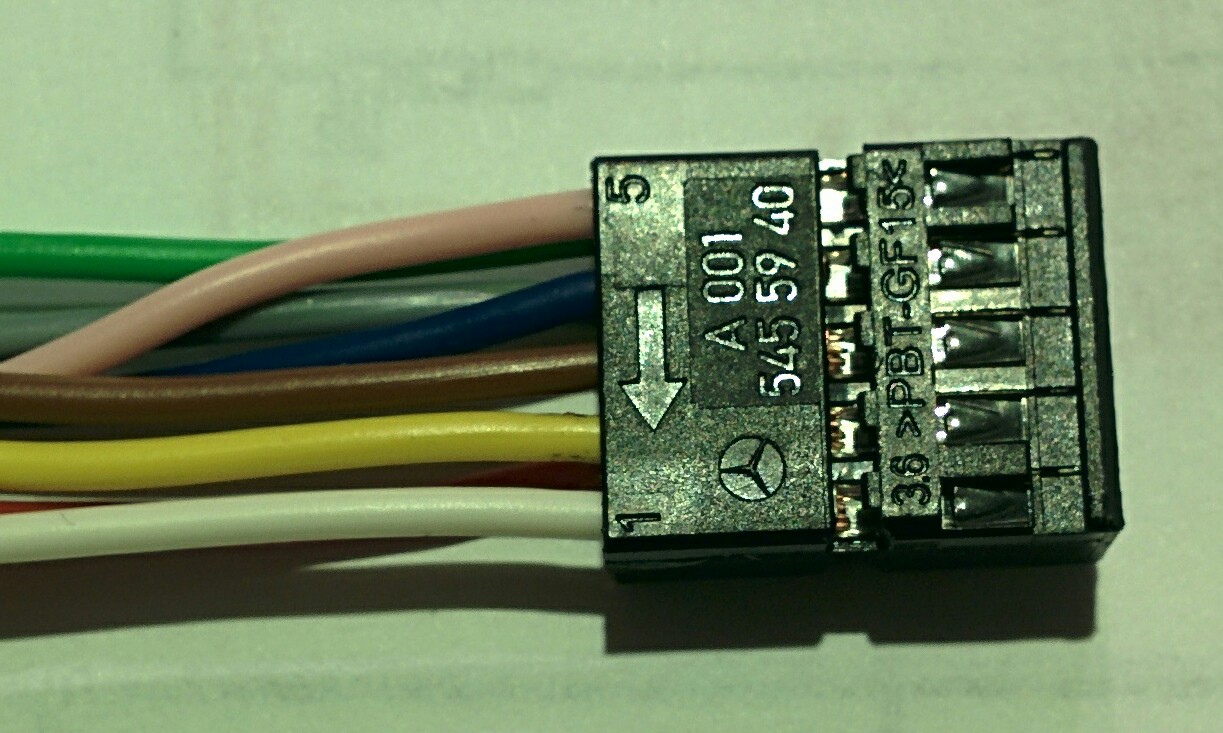

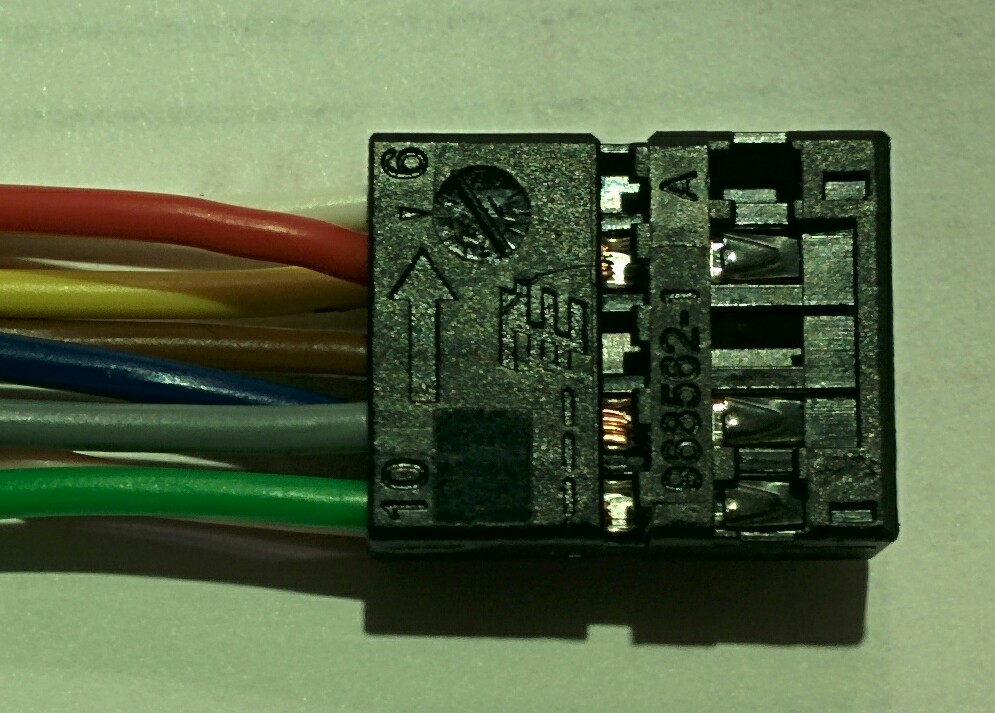

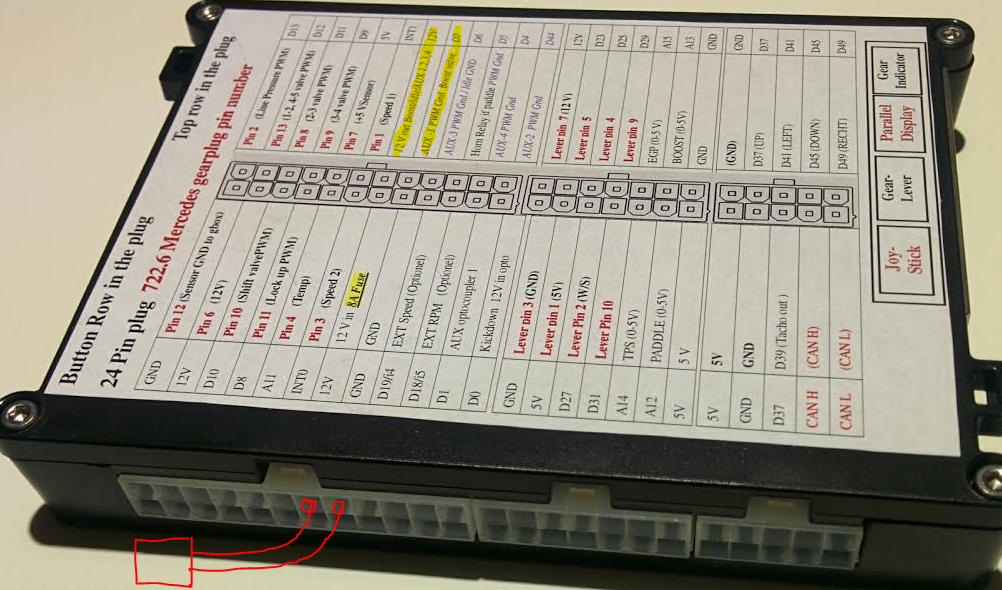

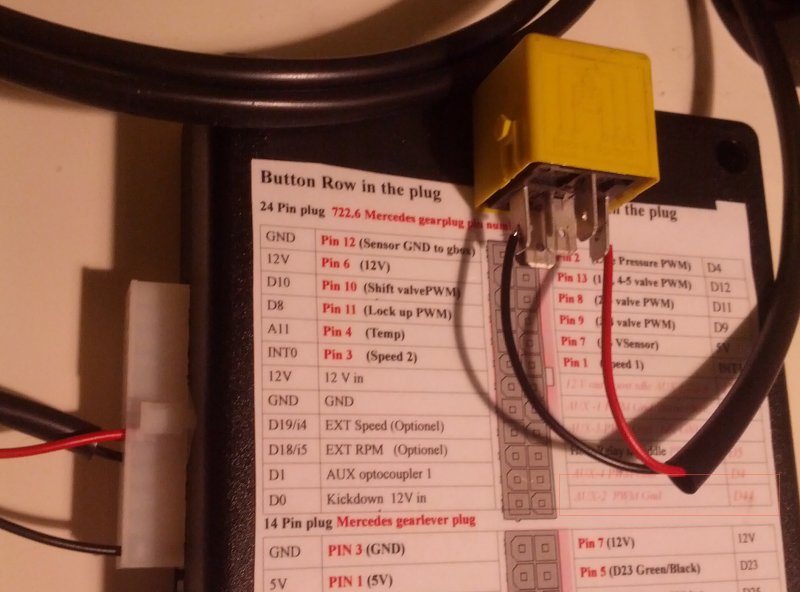

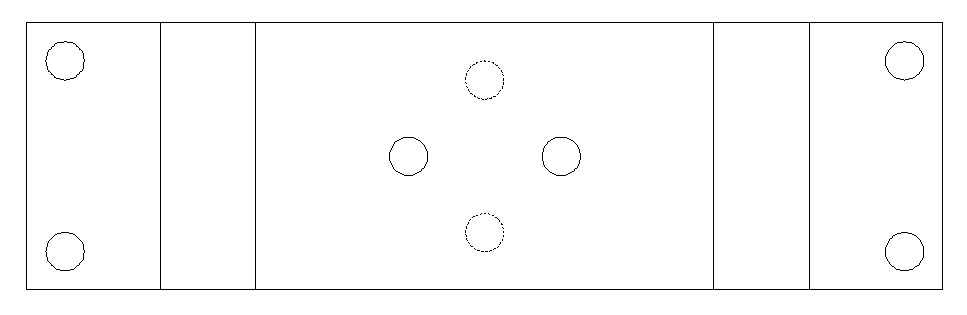

Gear Lever Connection 10

PIN MB plug to 14 Controller plug

24 Pin Gearbox Plug

Pinout from Controller

Use 8 Amp fuse on the 12 Volt

External Parts needed to

have a complete working system

Mercedes TPS Sensor from

W210 year 1997 - 2002

If you get the TPS sensor from a W210 car it has a

plug with 6 wires.

You need the plug and 10 cm of cable.

If you take the plug out you can read on the plug pin

1,2,3,4,5,6

the pin 1 needs to be connected to 5V,

the pin 6 needs to be connected to 0V,

the pin 5 needs to be connected to TPS input,

The last 3 wires from the Sensor is not connected.

MB TPS Sensor plug Mountet on an OM606

in a G Class, Mechanically pump

TPS Sensor MB

When TPS Sensor is mounted, you go into “setup Parameters” then “Setup Tps”

At 0%

TPS NO Throttle press the Up key

on joystick for 1 sec

Now press the

Throttle full to 100%

press DOWN

key for 1 sec

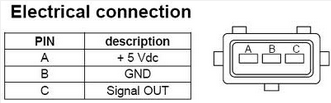

MERCEDES W210 E300 Turbo Diesel Boost Sensor If you need max 1,65 bar =

25 PSI

Then the originally MB boost sensor from a W210 E300

Turbodiesel can be used as it has a standard 0-5 volt output

I have only tested this exact type below

“Boost Control”

-> “General Boost” -> "0 point boost" set it to 305 if this Mercedes sensor is used

“Boost Control”

-> “General Boost” -> "Max boost at 5v" set it to 170 if this Mercedes sensor is used

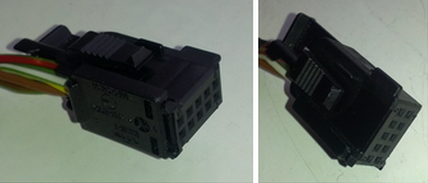

Gear Lever and plug (it

has to be the one with a “1” see red square on picture)

And the plug is a 10 pin, and have 8 wire out, thats

the Gear Lever we need

If you are in the Marked for a GearLever, be aware

that the GB (RHD), ones is also mirrord, compared to the LHD ones, an other

thing is that the one from W210 is longer and higher, then the W202, and R129

it is the short that fits the W124 and older G class,

W202 / R129 fits W124 W210

model Longer and higher then the one on the Left, Do NOT fit W124

Part number 2022670637

10 Pin plug to on the Wiring harness

Tiptronic Yes and No

I

can NOT talk to the Tiptronic shifter, if you want to use that, it is fine but

you then have no switch for W/S but that can be any switch.

And

I can only tell from the gearbox if you are in P/N od RD but that is fine but

the function width hold in 4, 3 2, 1, and so on are not working.

If

you want to use +/- You have to add some micro switch to switch to ground when

you press + or -

and

then connect to PADDLE input, thats it.

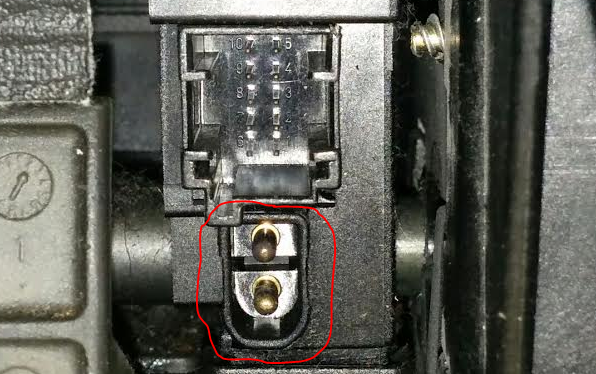

Reverse Ligth (Those 2 pin it shorted when i R

for Reverse Ligth)

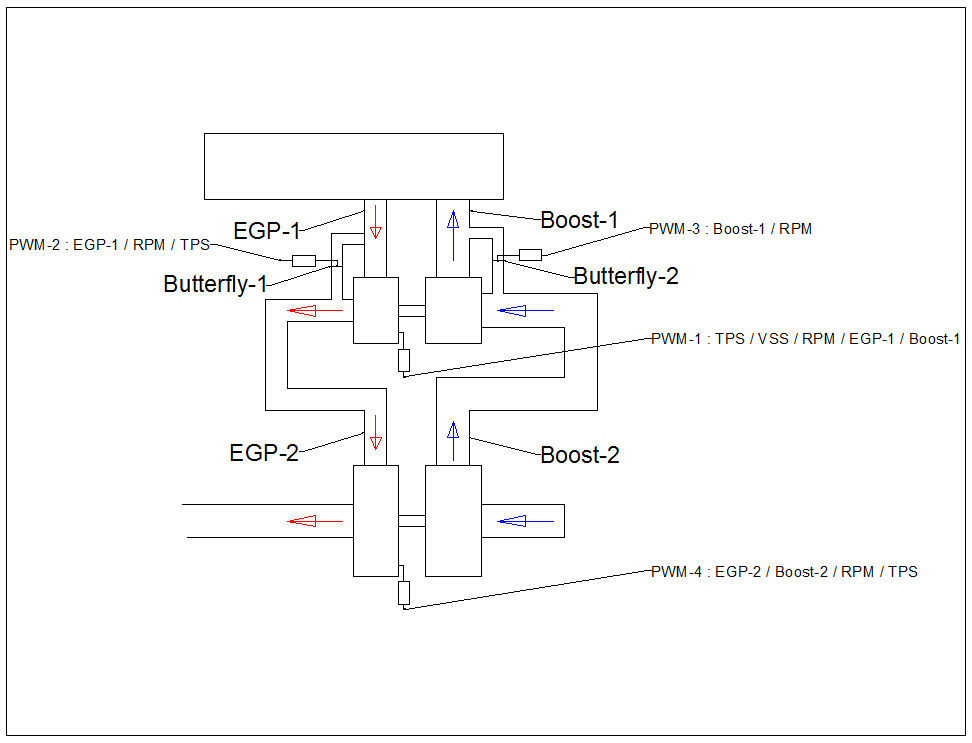

Boost

Controller, Parts to use

If you have a Vacuum actuated turbo where you want to

use the built in boost Controller you should have one of these.

This is a vacuum valve meaning if it has 100% PWM,

there are max vacuum = Wastegate closed, if 0% PWM no vacuum = Wastegate open.

The part is used in Many Mercedes cars from 1997 to

2000 both for boost control and EGR,

It is connected to

the two pins marked in red, it does not matter how they are connected as it is

a solonoid,

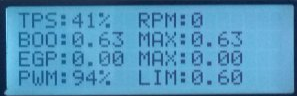

Here we see the

Boost screen We have set the Boost to 0,6 bar and the boost is 0,63 thats why

you see the PWM out is less then 100% = WasteGate is opening

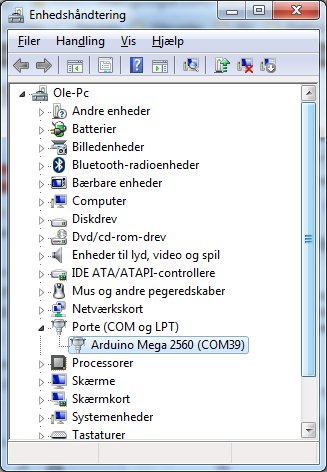

update of firmware

Install Driver

(Wery importent connect PC to controller when

stationary, as the controller restart when connected)

You need to connect

the box to you PC,

When connectet go

to Device Manager, here the Arduino Mega 2560 (and Port number) should show up.

But only if it

can find the rigth driver.

If it cant find

the rigth driver, you can download this package

https://drive.google.com/file/d/0B70ZSC6ltshQV2YxMkZzaXdiaWs/view?usp=sharing

it

is quite big, but you can’t just download the driver alone.

You

will find a directory called “Drivers”

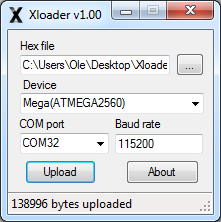

Update Firmware

Program

to upload new Firmware

Download

this software

http://russemotto.com/xloader/XLoader.zip

It will look like

this

Hex file send to you, is

choosen.

Device Choose

(Mega(ATMEGA2560)

Comport (To find you comport look in Device

Manager )

Press Upload and wait until it says uploaded it takes

around 60 second

Starter Lockout (from version 113)

“Boost

Control” -> “General Boost” -> “USE PWM - AUX-2”

If

set to “2” then the AUX-2 works as a Starter Lockout, it pulls the output to ground

when in P or N

This

can drive a relay, witch has 12 Volt on the other side of the coil. (from

version 113)

I

know it does not make sence this function is hidden in the Boost menu, but as

we steal a AUX output from there, thats why.

The

starter lockout will work no matter if you don't have the Mercedes Gear Lever

og you running without a Gear Lever.

You

can not use AUX-2 to other things at the same time.

Boost Controller part of the 722.6 controller.

The

Boost controller can be used in different ways.

If you

want to use Boost Controller

Goto

“Boost Control” -> “General boost” -> “VNT Boost/EGP”

The value means the following

0 Boost Controller in PWM

mode allow, you to specify PWM depending on boost, see later in this document)

1,

2, 3, 4 is for VNT Turbos 4 different algorithm to adjust boost

5

is for Normal Turbo

6

is for Normal Turbo more aggressive

limit

7 is for Normal Turbo even

more aggressive limit

8,9,.....................

20 extreme aggressive limit

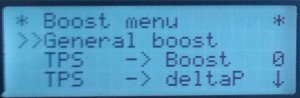

At the bottom we have the

Boost Control menu

In there is a General Boost,

and all the many data points you can change

Lets

say you have an normal Turbo, just want to open wastegate when boost hits 1 bar

Goto

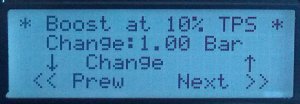

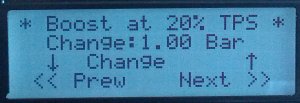

“Boost Control” -> “TPS -> Boost”

Press

-> on the joystick.

Here

below you have 11 data points for any throttle position, 0.10.20.30....100%

Right

key gives you next point, Left gives you previous.

Up

key higher value, Down lower value

Check

out this YouTybe Video

http://www.youtube.com/watch?v=ULEGavGRavs

To

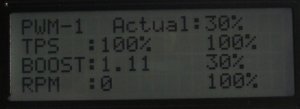

see what you have programmed you watch the live data in the live data menu.

Here

you see that TPS is 41% and the Limit is set to be max 0.6 bar boost = 9 PSI.

at that throttle position. But as you see boost are a little higher, that's why

the PWM out is not 100% it has started to open the Wastegate on the turbo.

If you want More Control over

what happens, you can specify exactly what PWM signal is sent to the Boost

valve.

PWM

is Puls width Modulation. if it is 10% that means that yeo have 10% power to

the solonoid valve, and wastegate is almost fully open

If

PWM is set to 100% the solonoid will make full vacumm and wastegate will close

Goto

“Boost Control” -> “General boost” -> “VNT Boost/EGP” set value to “0”

Goto

“Boost Control” -> “General boost” -> “Use PWM-1 Boost” set to “1”

Now

the menu has Changed and ready to do PWM.

Goto

“Boost Control” -> “EGP-Boost ->

% PWM” set what you want here

Goto

“Boost Control” -> “Boost ->

% PWM” set what you want here

Goto

“Boost Control” -> “RPM ->

% PWM” set what you want here

Goto

“Boost Control” -> “Speed ->

% PWM” set what you want here

The

lovest PWM value will be taken from the above and send to Valve

On

Picture below you see that the boost limits PWM to 30 %

Holset CAN-BUS Control fromSW ver_144

And HW ver 4 the new Smaller SMD board

The Holset HE351VE is a

popular VNT turbo, that is why i now support to run this turbo over the CANBUS

output.

Goto “Boost Control” ->

“General boost” -> “CANBUS” set it to

“HOLSET 1” or “HOLSET 2” if set to HOLSET 2 it moves the vanes the other

direction.

Goto “Boost Control” ->

“General boost” -> “VNT Boost/EGP”

set it to “0”

Now Restart the controller 2

times.

The Controller now control

the Turbo depending on the settings in

Goto “Boost Control” ->

“EGP-Boost -> % PWM” set what

you want here

Goto “Boost Control” ->

“Boost -> % PWM” set

what you want here

Goto “Boost Control” ->

“RPM -> % PWM” set

what you want here

Goto “Boost Control” ->

“Speed -> % PWM” set

what you want here

%PWM is % position of the

vnt vanes in this mode.

Connect the Holset, there is 4 wire coming out the

Holset controller

RED / Green = 12V

Green / yellow = 0V GND

Yellow = CAN H

Green = CAN L

Picture of my test setup

Extra AUX output

for other stuff

There are 3 more PWM AUX output,

AUX-2

“General Boost” -> “USE AUX-2”

If Use “USE AUX-2” is set to “1” Then it works this way

The AUX-2 PWM out. takes input from the TPS, EGP, RPM

and gives out the lowest of the 3.

From ver 159 (Start Fan for Gear oil Cooler)

If Use “USE AUX-2” is set to “3” Then it works this way

The AUX-2 PWM out. Takes input from Gear oil temp and

Pulse AUX-2 to ground at higher then 90° and releases at 85°

if “USE AUX-2” is set to “2” then it is used as starter lockout. (search for starter lockout)

If “USE AUX-2” is set to “3” then the signal is used to pull the solonoid on the Gearlever, then it

can not be moved in to R and P while driving more then 10 km/h (It gives a ground signla, you have to supply

12V to the other side of solenoid)

AUX-3

If “USE AUX-3” is set to “1”

This takes in Analog input 1 in and Boost, RPM, and

gives out the lowest PWM of the 3 out

.

This output is also used for reversing Ligth

if Lever is set to “2” and can then not be used for AUX-3

If “USE AUX-3” is set to “3” Then

the signal is used to pull the solonoid on the

Gearlever, then it can not be moved in to R and P while driving more then 10

km/h (It gives a ground signla, you have

to supply 12V to the other side of solonoid)

If “USE AUX-3” is set to “4” Then it works this way

The AUX-3 PWM out. takes input from Gear oil temp and

pulse AUX-3 to ground at higher than 90° and releases at 85°

AUX-4,

Same as previous just another analog input. (if set to 1 it is used depending on

A-2,Boost,RPM)

This output can also be used to get a signal out to

limit power of engine.

Under “General Boost” go to “Use PWM - AUX-4”,

The following happens for different value

1, it

is used depending on A-2,Boost,RPM as AUX, not Pover limit function.

2, you

get instant 200 mS 100% PWM

3, you

get instant 300 mS 100% PWM

12 you

get 100 mS delayed 200 mS 100%

PWM (1 is 100mS delay the 2 is 200-100 = 100 mS signal)

25 you

get 200 mS delayed 500 mS 100%

PWM (2 is 200mS delay the 5 is 500-200 = 300 mS signal)

By the way Engine

limit only works at TPS > 20% (prevent stop engine at low RPM)

AUX-4 Explanation

Analog in 0-5 volt

out = PWM signal 50% means valve on half the time.

|

0 |

0,5 |

1 |

1,5 |

2 |

2,5 |

3 |

3,5 |

4 |

4,5 |

5 |

|

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

90 |

75 |

30 |

Boost in PWM out

|

0 |

0,15 |

0.3 |

0,45 |

0,6 |

0,75 |

0,9 |

1,05 |

1,2 |

1,35 |

|

100 |

100 |

100 |

100 |

100 |

100 |

60 |

30 |

0 |

0 |

RPM in PWM out

|

0 |

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

|

100 |

100 |

100 |

100 |

100 |

100 |

100 |

80 |

60 |

40 |

If we have

A-2 = 4,5 Volt <=> 75%,

Boost = 0,9 bar <=> 60%, This is the lowes and 60% PWM is sent to the

Valve.

RPM = 3500 <=> 80%,

Just a little more work then 2 X VNT in Compound

This is the Label on the V3 Controller

Failure Search

**Start Fail

RPM-1** or **Start Fail RPM-2**

There is a safety feature in the boxes, that locks all

shifts if speed is not right,

This can be triggered if put ignition on and start the

car instant, Specially if you also gives it a little gas

If you put ignition on and start after 2 sec you will

never see it.

**N at speed**

There is a safety feature in the boxes, that locks all

shifts if put in N at

speed

Please drive below 5 km/h before put in N

GearOil

It is very important that the gear Oil level is

correct in the 722.6 but if you don't

have a dipstick here is how you can make you own. as the 722.6 newer has a

dipstick from new.

Mercedes Part number : 140589152100

http://autoimport.dk/mercedes_webcatalog/search/?q=KA-6953

http://mbspecialist.com/mercedes_webcatalog/search/?q=KA-6953&search-button.x=0&search-button.y=0

Here is a link to discussion of Oil Level

SpeedoMeter

Great Link to keep speedo working on old cars from

here

http://www.peachparts.com/shopforum/diesel-discussion/308791-380sl-diesel-conversion-project-15.html

FROM the link

But I figured out how to move the

internal VR trigger wheel to the driveshaft and keep the tailcone with the

manual speedo on the 722.4. Here's a diagram of the strategy. (The full thread

on this topic, including images of the proof-of-concept test is here - Mechanical

to Electronic Speedometer Conversion

)

Different information

Momentum for the 722.6 (W5A580)- 578lb/ft = 800 Nm

i

think the strongest automatic 722.6 is the 722.649 this is connected

to

the 65 amg and handle 1000nm

722.608

300 td diesel

722.623

some v8 petrols

722.649

e65 amg,s

Gear ratios

|

Mercedes-Benz Transmissions |

|||||||

|

Gear |

1 |

2 |

3 |

4 |

5 |

R1 |

R2 |

|

5G-TRONIC

(W5A330/Small NAG)[2] |

3.932 |

2.408 |

1.486 |

1.00 |

0.83 |

-3.10 |

-1.90 |

|

5G-TRONIC (W5A580/Large NAG)[3] |

3.59 |

2.19 |

1.41 |

1.00 |

0.83 |

-3.16 |

-1.93 |

Where to find

the gearbox

·

1996–1999 Mercedes-Benz

W140

·

2000-2005 Mercedes-Benz

W220

·

2006–Present Mercedes-Benz W221 (V12 Models only)

·

1997-2002 Mercedes-Benz

W210

·

2002-2004 Mercedes-Benz

W211

·

1997-2000 Mercedes-Benz

W202

·

2000-2004 Mercedes-Benz

W203

·

1998-2005 Mercedes-Benz

W163

·

1997-2004 Mercedes-Benz

W168

·

2004–Present Mercedes-Benz

W169

·

2005–Present Mercedes-Benz

B-Class

·

1998-2005 Mercedes-Benz

R170

·

1990-2001 Mercedes-Benz

R129

·

2001–Present Mercedes-Benz R230 (V12 Model and Earlier, up to

2005)

·

1998-2002 Mercedes-Benz

W208

·

2003-2005 Mercedes-Benz

W209

·

2000-2006 Mercedes-Benz C215 (V12 Models only)

·

2007–Present Mercedes-Benz C216 (V12 Models only)

·

1996–Present Mercedes-Benz W463 (AMG Models only)

·

2005-2009 Mercedes-Benz

SLR

·

2002–Present Maybach

57 and 62

·

1998-2002 Jaguar X308 (Supercharged models only)

·

1998-2002 Jaguar XK (X100) (Supercharged models only)

·

2004–Present Ssangyong

Rexton

·

2006–Present Ssangyong

Kyron

·

2005–Present Ssangyong

Rodius

·

2005-2008 Dodge Magnum- All HEMI applications, all AWD

applications and some 3.5L RWD V6 applications, year dependent

·

2005–Present Chrysler 300- All HEMI applications, all AWD

applications and some 3.5L RWD V6 applications, year dependent All pentastar V6

applications

·

2006–Present Dodge Charger- All HEMI applications, all AWD

applications and some 3.5L RWD V6 applications, year dependent,All pentastar V6

applications

·

2008–Present Dodge Challenger- All HEMI applications, All

pentastar V6 applications

·

2007-2011 Dodge

Nitro- 4.0L V6 Applications

·

2006-2010 Jeep Commander- 3.7L V6 Applications, 3.0L CRD V6

applications

·

2005–Present Jeep Grand Cherokee- 3.7L V6 Applications, 3.0L Diesel

Applications, SRT8 Applications, all pentastar V6 applications

·

2011–Present Dodge

Durango, 3.6L V6

·

2011–Present Jeep

Wrangler- 2.8L Diesel

·

2012–Present Jeep

Wrangler 3.6L V6

As

much as I hate to say it, here it is…

This product comes

with no warranties or guarantees of any kind. Both installation and use of

this system in any

vehicle is done at the risk of the owner / operator of the vehicle. The

developer / seller of

this system cannot be held responsible for any loss, damages or injury

caused either

directly or indirectly by the installation or use of this system. The

system is

intended for off road

use only.

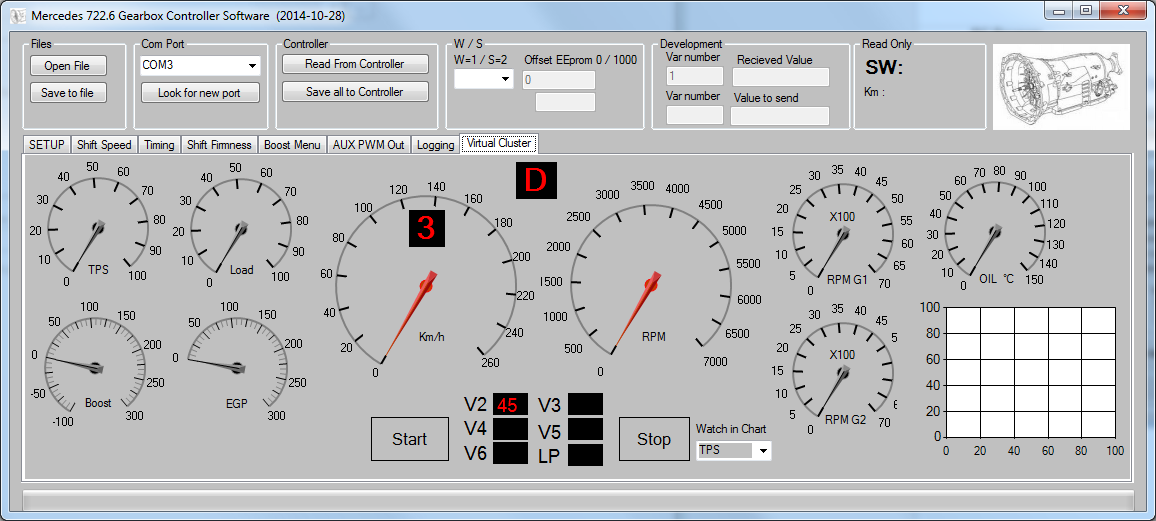

PC Program (This is Beta, not 100% tested)

DO NOT CONNECT AND DISCONNECT USB CABLE WHILE Driving

Get the EXE file direct, and run

https://drive.google.com/file/d/0B70ZSC6ltshQMnpsRm96d09HMGM/view?usp=sharing

Driver for

controller

https://drive.google.com/file/d/0B70ZSC6ltshQV2YxMkZzaXdiaWs/view?usp=sharing

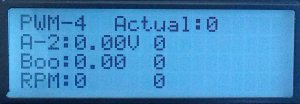

Conversion drawing

W124

Engine from OM603 to OM606

Gearbox from 722.3 to 722.6

The Propellershaft do not need to be changed or

modified, just make sure the Flange fit.

If you have mecanically Tacho you can find a

electronic one from W124 (420 or 500) make sure they are eletronic.

The Crossbare from any W210 can be used but 2 holes

has to be drilled.

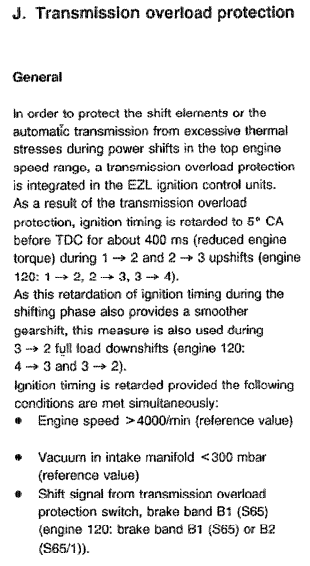

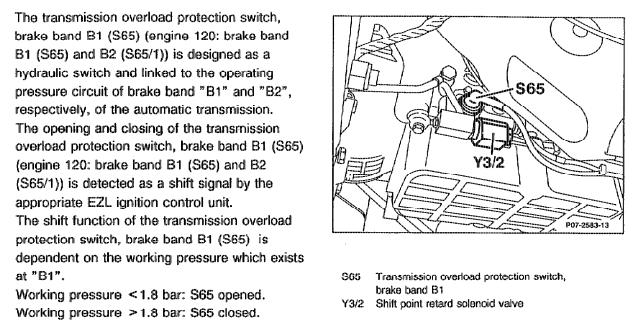

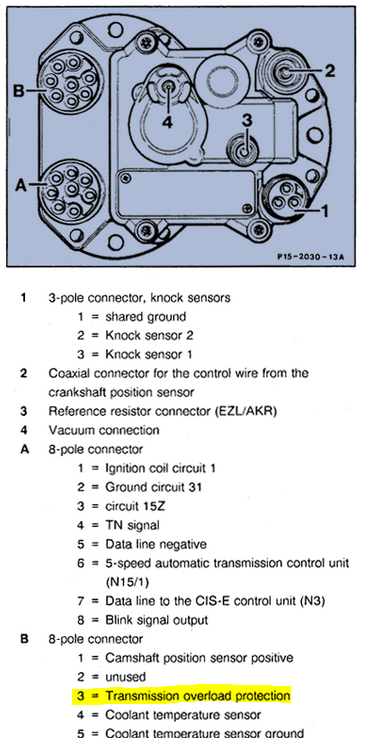

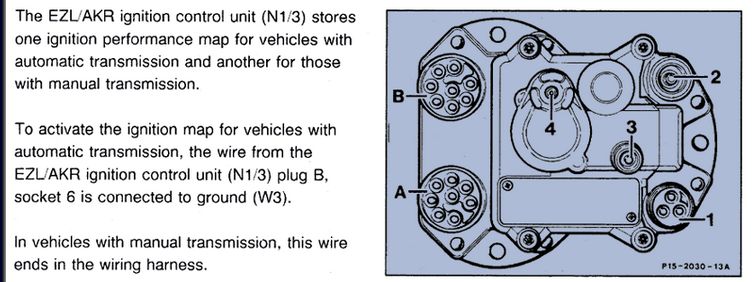

Overload protection

on W124 gasoline cars, (NOT NEEDED BUT

POSSIBLE)

this controller can also send a signal to the Engine

controller

But i

have not yet tried it, all info i have found is below here

Please if

anyone know how the S65 switch is working, please tell me, what i think is that

it is just short the 2 wires but not sure. ?

If it works as i think the S65 simply short 2 wires. ?

if it is like that then mount a relay to short, and drive the relay, width the

output from controller.